Glassline Repair Services

Introduction to Glassline Repair Services

Shree Ram Sealing Engineers is a trusted name in industrial leak sealing and cold welding solutions. Through our Cold Welding Division, we offer professional glassline repair services for chemical and industrial storage equipment.

Glass-lined tanks are popular in chemical industries because they resist corrosion. However, chemical exposure, mechanical damage, or operational stress can cause cracks, pinholes, or leaks over time. Our expert engineers provide on-site repair solutions using advanced adhesive putty and glassline repair compounds—no hot work required. This means less downtime and long-lasting results for your equipment.

Benefits of Our Glassline Repair Solutions

We perform all repairs at your facility without dismantling or removing equipment.

Cold application process ensures complete safety in hazardous chemical storage environments always.

Fast repair execution minimizes production interruptions keeping your manufacturing operations running smoothly continuously.

Our repair solutions cost significantly less than expensive tank replacement or lengthy shutdown.

Advanced materials withstand highly corrosive acidic and alkaline substances for extended periods.

Professional quality repairs deliver durable long lasting performance reducing future maintenance requirements.

Why Choose Shree Ram Sealing Engineers

Our skilled technical engineers possess proven expertise in complex industrial leak sealing applications.

Dedicated cold welding and leak sealing specialists with years of hands-on field experience.

We design and manufacture our own high-performance adhesive putty ensuring superior repair quality.

Every repair is tailored specifically to meet your unique operational requirements and challenges.

Successfully serving chemical pharmaceutical and manufacturing industries across India with excellent results.

Round the clock emergency response team ready to handle urgent tank leakage and repairs.

Types of Glassline Repair Services We Provide

-

1. SS Chemical Storage Tank Inner Surface Repair

We specialize in repairing the inner lining of SS chemical storage tanks using our SR Glassline Repair Putty. This method restores damaged areas without dismantling the tank.

-

2. Repair for Low pH Chemical Storage Tanks

Our solutions are suitable for tanks storing highly corrosive chemicals, including pH level 2 chemicals, where conventional welding is unsafe or impossible.

-

3. Pin Hole and Leakage Repair

We effectively seal: Single pinhole leaks Multiple leakage points (2–3 holes or more) Hairline cracks and surface damage All repairs are performed without draining the tank, wherever possible.

Common Problems We Solve

Industries frequently face these challenges with glass-lined and chemical storage tanks:

-

Chemical leakage from pinholes or damaged lining

Small holes and cracks in tank lining allow hazardous chemicals to escape causing operational disruptions.

-

Corrosion caused by acidic chemicals

Highly corrosive low pH chemicals gradually deteriorate tank surfaces leading to structural weakness and potential failure.

-

Risk of contamination and safety hazards

Leaking chemicals can contaminate products pollute environment and pose serious health risks to workers nearby.

-

High downtime and production losses

Tank failures force unexpected shutdowns resulting in lost production time missed deadlines and reduced profitability.

-

Expensive tank replacement or shutdown for welding repairs

Traditional repair methods require complete tank replacement or costly welding shutdowns draining your maintenance budget significantly.

Our Repair Process

-

Step 1: On-Site Inspection Our technical engineers visit your facility to thoroughly inspect the damaged area. We identify:

Type and extent of damage – We assess crack depth pinhole size and lining deterioration to determine the severity of damage.

Chemical compatibility requirements – We verify which chemicals are stored to select appropriate repair materials that resist chemical attack effectively.

Operating conditions (temperature, pressure, pH level) – We evaluate tank operating parameters to ensure repair materials can withstand your specific environmental conditions safely. -

Step 2: Problem Diagnosis:

After inspection, we determine the root cause of the leakage, such as chemical attack, lining failure, or mechanical stress.

-

Step 3: Solution Recommendation We recommend the most suitable repair method and materials, typically using:

SR Glassline Repair Putty – Our specially formulated putty provides excellent adhesion chemical resistance and durability for long lasting tank repairs.

Chemical-resistant adhesive compounds – Advanced industrial grade compounds create strong bonds that withstand corrosive chemicals and harsh operating environments permanently.

Cold welding techniques – Non thermal bonding methods eliminate fire hazards while delivering permanent repairs without compromising tank structural integrity. -

Step 4: Repair Execution We carry out the repair safely with:

No hot work required – Our cold application methods eliminate fire risks spark hazards and hot work permits for safer repairs.

Minimal surface preparation – Quick preparation processes reduce labor time and allow faster repairs without extensive grinding or cleaning procedures.

Fast curing time – Rapid setting materials enable quick return to service minimizing downtime and getting your operations running again.

Get Your Tank Repaired Today

If your glass-lined or chemical storage tank has leakage, corrosion, or lining damage, Shree Ram Sealing Engineers provides a safe, reliable, and economical solution. Our glassline repair services help you restore equipment integrity, reduce downtime, and extend the life of your assets—all without shutdown or hot work.

Contact us today for an on-site inspection and customized repair solution.

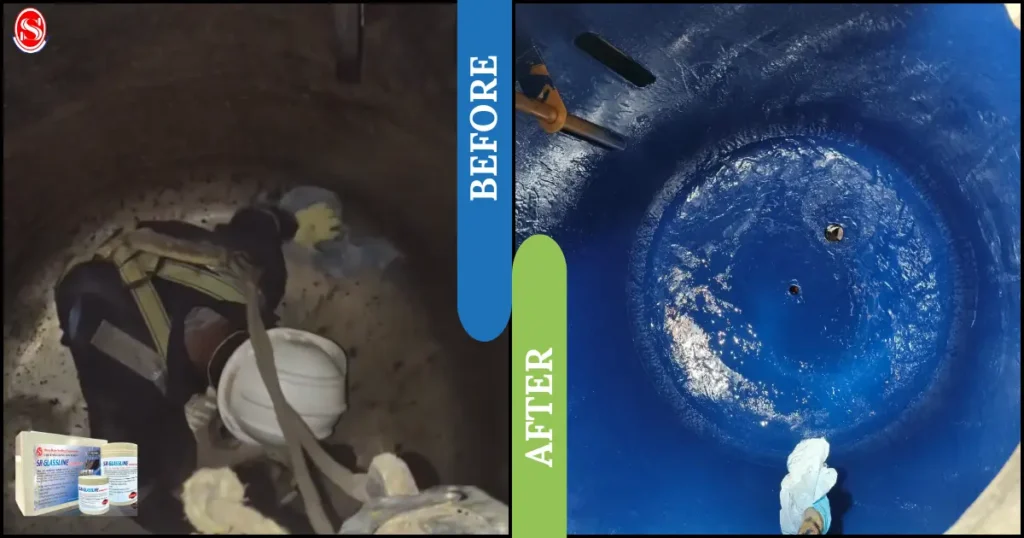

Live Repair in Chemical Storage Tank

Glass line repair in Chemical Storage Tank

Chemical storage tank glassline putty

High-strength Chemical Storage Tank Repair With Glassline Putty

Glass-line Storage Chemical Tank

Glass-line repair putty in Storage Chemical Tank

Contact our technical expert for a customized solution to your operational challenges