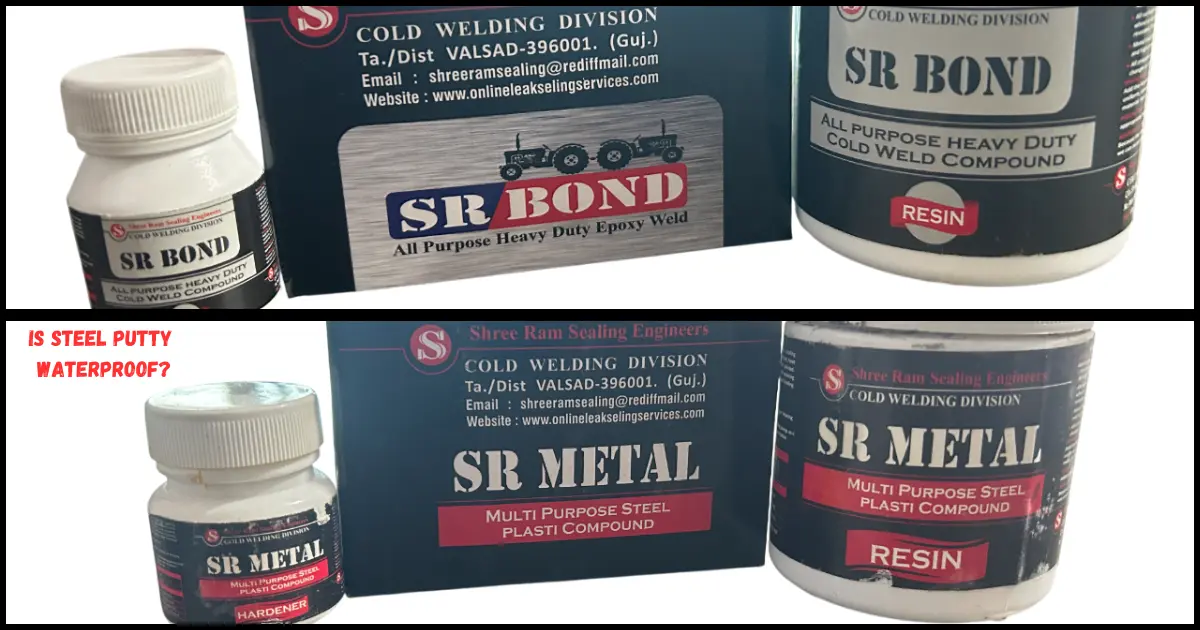

Understanding Steel Putty Products

Steel Putty Products are widely used for repairs in many industries due to their strength and durability. These products are great for fixing cracks, sealing joints, and restoring damaged surfaces. A common question people have is whether steel putty is waterproof.

Steel putty has evolved over the years to become an indispensable solution for industrial and household repairs. From fixing small leaks to reinforcing structural components, its applications are vast and varied. The answer to its waterproof capabilities lies in its unique composition and performance.

Steel putty is a two-part adhesive compound made from epoxy resin and steel particles. It’s engineered to bond strongly to metal surfaces, providing a robust solution for structural repairs. When cured, steel putty achieves a hard, metallic finish that can withstand extreme conditions.

It is commonly used in:

- Repairing pipelines and tanks

- Fixing cracks in machinery

- Sealing joints in plumbing systems

With its strong adhesion and metallic properties, steel putty has become a go-to material for quick and reliable repairs.

The composition of steel putty typically includes:

- Epoxy resin: Acts as the binding agent, ensuring a strong bond.

- Steel particles: Provide reinforcement, enhancing the material’s strength and thermal resistance.

- Curing agents: Facilitate the hardening process, allowing the putty to solidify into a durable state.

Some advanced formulations also include additional additives to improve flexibility, temperature resistance, or chemical stability. This unique composition enables steel putty to perform well under pressure, making it suitable for industrial and household applications.

Resistance to Water

Steel putty exhibits excellent water resistance once fully cured. The epoxy resin in its formula forms a non-porous, waterproof barrier that prevents water infiltration. This makes it an ideal choice for sealing leaks in pipes, tanks, and other metal structures exposed to moisture.

Its water-resistant nature also protects against weathering, ensuring the integrity of the repair even in challenging environmental conditions.

Applications in Wet Environments

Thanks to its waterproofing capabilities, steel putty is widely used in:

- Marine repairs: Fixing cracks in boat hulls and underwater equipment.

- Plumbing: Sealing leaks in pipes and joints.

- Industrial settings: Repairing tanks and machinery subjected to wet conditions.

- Automotive repairs: Fixing radiators and other components exposed to water.

Methods to Test Waterproofness

To confirm the waterproof properties of steel putty, several testing methods are employed:

- Submersion test: The cured putty is submerged in water for extended periods to check for water penetration.

- Pressure test: Subjecting sealed surfaces to high water pressure to ensure integrity.

- Durability test: Evaluating the material’s resistance to prolonged exposure to moisture.

These tests are crucial for verifying the performance of steel putty in real-world scenarios where water resistance is a critical requirement.

Real-World Performance

In real-world applications, steel putty has consistently demonstrated its ability to resist water effectively. Industries such as oil and gas, marine, and construction rely on its waterproofing properties to ensure reliable repairs in demanding environments.

Field tests and case studies have shown that steel putty maintains its adhesion and waterproof barrier even when subjected to fluctuating temperatures and continuous water exposure.

Enhancing Durability

Waterproof steel putty adds an extra layer of protection to repaired surfaces, enhancing their lifespan. By preventing water ingress, it helps maintain the structural integrity of metal components.

This durability translates to cost savings, as repairs last longer and require less frequent maintenance.

Preventing Corrosion

Metal surfaces are prone to rust and corrosion when exposed to moisture. Steel putty acts as a shield, blocking water contact and reducing the risk of corrosion. This feature is especially valuable for outdoor and industrial applications.

By preventing rust, steel putty also enhances the aesthetic appeal and functional reliability of repaired components.

Versatility in Application

The waterproof nature of steel putty allows it to be used across a range of industries and conditions, including underwater repairs. Its ease of application and quick curing time make it a preferred choice for emergency fixes.

Steel putty’s composition and properties make it a reliable choice for waterproofing applications. Its ability to form a strong, water-resistant barrier ensures durability and protection in various environments. Whether dealing with small plumbing issues or large-scale industrial repairs, steel putty proves to be a dependable solution.