Atul Ltd is a leading integrated chemical company serving over 4,000 customers across 30 industries worldwide. Founded in 1947 by visionary Kasturbhai Lalbhai, Atul aims to create employment, promote rural development, and make India self-reliant in chemical production. With advanced technology, the company manufactures around 1,350 products while maintaining strict safety and environmental standards, holding ISO 14001 certification.

Recently, Atul Ltd faced a critical challenge: a leak in their Limpet Coil Reactor. This issue halted production, disrupting workflows and leaving employees unable to perform their tasks. To resolve this, they required an immediate and effective solution to restore operations swiftly.

Atul Ltd encountered a significant operational disruption when a Limpet Coil Reactor at their facility developed a leak. This reactor is integral to their production process, which involves manufacturing and processing industrial chemicals like Ferrous Sulphate and Activated Carbon. The leak halted production entirely, directly impacting their ability to fulfill orders and maintain workflow continuity.

The downtime caused by the leak was further compounded by the inability of employees to continue their work, leading to lost productivity and financial strain. Given the competitive nature of the chemical manufacturing industry, the situation demanded an immediate and effective resolution. Prolonged delays risked damaging customer trust and disrupting supply chains, making it crucial for Atul Ltd to address the issue without delay.

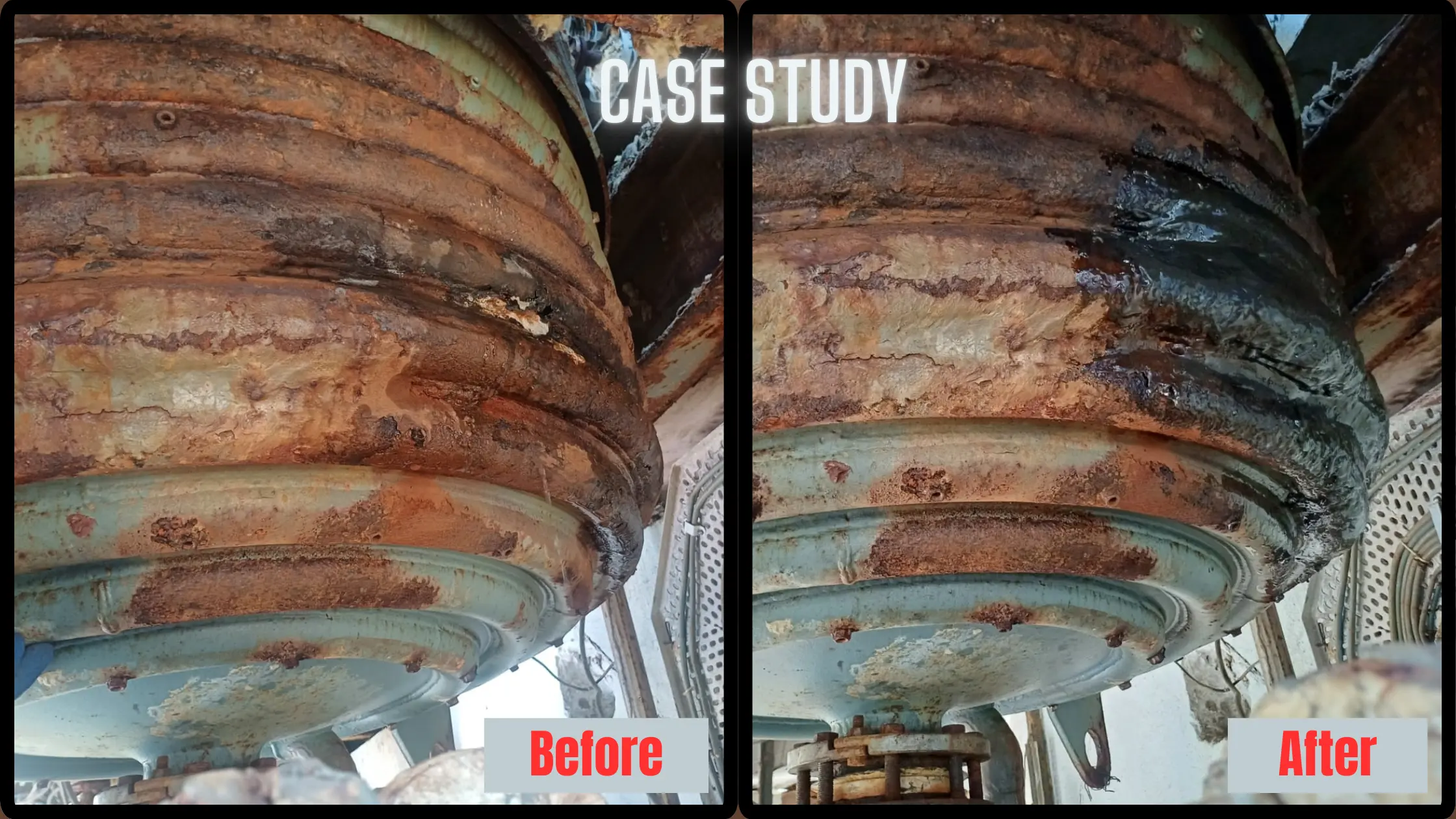

To address the Limpet Coil Reactor leak, Shree Ram Sealing Engineers implemented a comprehensive solution using SR Steel Bond adhesive steel putty, a high-strength repair material ideal for such industrial applications. The approach began with cleaning the reactor's affected areas to remove rust and contamination, ensuring optimal adhesion and performance of the putty. The repair was executed without shutting down the rest of the facility, minimizing operational disruption. This unique strategy allowed Atul Ltd to maintain productivity in unaffected areas while addressing the critical reactor issue. Additionally, the application of SR Steel Bond not only sealed the leak effectively but also extended the reactor's lifespan, enhancing its reliability and reducing future maintenance costs. This solution was an excellent fit for Atul Ltd needs. It provided a cost-effective repair, preserved the reactor's usability for an extended period, and avoided the significant financial losses associated with a full shutdown. The strategic implementation reinforced the company's operations without compromising its commitment to delivering high-quality products to its clients.

Implementation Approach

- Preliminary Cleaning: The reactor’s surface was cleaned thoroughly to remove rust and contaminants, ensuring a strong bond and effective repair.

- Application of SR Steel Bond: The adhesive steel putty was applied to seal the leak and reinforce the reactor’s structural integrity.

- On-Site Repair: The repair process was executed on-site, maintaining a working pressure of 4 kg/cm² and temperature conditions up to 150°C.

- Prolonged Reactor Life: The repair not only addressed the immediate leak but also enhanced the reactor’s durability, extending its operational lifespan.

In the case of Atul Ltd, SR Steel Bond adhesive steel putty played a pivotal role in addressing the Limpet Coil Reactor leak. This advanced product was specifically chosen for its durability, chemical resistance, and ability to withstand high pressures and temperatures, making it ideal for industrial reactor repairs. The application process began with a thorough cleaning of the reactor surface to remove rust and debris, ensuring optimal adhesion of the putty. Once applied, SR Steel Bond effectively sealed the leak, restoring the reactor’s functionality without requiring downtime for other facility operations. The product's unique properties, such as its high tensile strength and quick curing time, ensured that the repair was not only efficient but also long-lasting. This solution enhanced the reactor’s lifespan, significantly reducing future maintenance needs and operational costs for Atul Ltd. The repair also demonstrated the versatility and reliability of SR Steel Bond, proving its value in critical industrial applications. This success story underscores the effectiveness of SR Steel Bond in tackling complex equipment challenges while ensuring minimal disruption to business operations.

After implementing the solution, Atul Ltd experienced significant improvements in their operations:

- Immediate Resolution of Reactor Leak: The use of SR Steel Bond adhesive steel putty effectively sealed the Limpet Coil Reactor leak, allowing the reactor to resume normal operations without delay.

- Minimal Downtime: By avoiding a complete shutdown, the repair process ensured continuity in unaffected production areas. This minimized operational disruption and preserved revenue streams during the repair period.

- Extended Reactor Lifespan: The high-strength putty enhanced the reactor’s durability, increasing its lifespan and reducing the frequency of future maintenance. This improvement contributed to long-term cost savings.

- Cost-Effectiveness: The solution was implemented at a fraction of the cost compared to alternatives, aligning with Atul Ltd financial goals.

- Restored Productivity: Employees resumed work promptly, addressing the downtime caused by the leak and ensuring that production schedules remained on track.

The partnership between Atul Ltd and Shree Ram Sealing Engineers successfully addressed a critical operational challenge. By utilizing SR Steel Bond adhesive steel putty and applying innovative repair techniques, the Limpet Coil Reactor was restored without halting production. This solution minimized downtime, extended equipment lifespan, and saved costs, allowing Atul Ltd to continue delivering high-quality products to their clients. This case highlights the importance of timely, cost-effective solutions in industrial operations. It also emphasizes how tailored approaches can resolve technical challenges while maintaining business continuity. If your business is facing equipment leaks or operational challenges, we can help. Contact Shree Ram Sealing Engineers for expert solutions that save time, reduce costs, and boost operational efficiency. Visit us at onlineleaksealingservice.com or schedule a personalized consultation today to learn how our services can transform your operations. Let’s work together to keep your business running smoothly!