Introduction: Fix Leaks Fast with a Pipe Leak Repair Kit

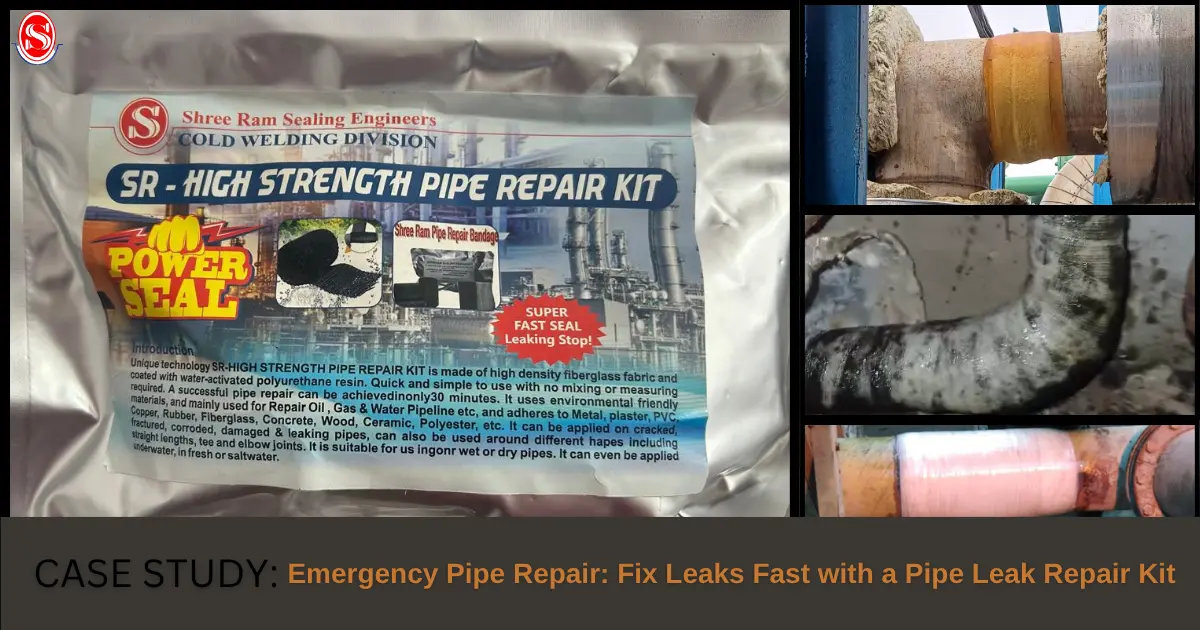

Pipe leaks can disrupt operations, cause costly damage, and halt production in industries like power plants and chemical factories. Whether it’s a small leak in a processing line or a major burst in a critical pipeline, the consequences can be severe—water damage, equipment failure, or safety hazards. The Shree Ram Pipe Repair Kit, available through distributors at onlineleaksealingservice.com, offers a fast, reliable solution for emergency pipe repairs. In industrial settings, these kits enable maintenance teams to fix leaks quickly without shutting down systems, thus saving time and money while ensuring operational continuity. In this article, we’ll explore how these kits work, their benefits for industries, and why Shree Ram Pipe Repair Bandages are a top choice for distributors and facility managers.

A pipe leak repair kit is a specialized set of tools and materials designed to seal pipe leaks quickly, even in high-pressure industrial environments. These kits are a lifeline for power plants, chemical factories, and other industries where downtime is not an option. Common components include:

- Self-fusing Tape: A flexible tape that forms a watertight seal by bonding to itself.

- Epoxy putty: a moldable compound that hardens to fix small leaks or cracks.

- Fiberglass Repair Bandages: Combined with water-activated resin, these create a durable, long-lasting seal.

- Pipe Clamps: Used to stabilize larger leaks or bursts temporarily.

- Water-activated Resin: Hardens quickly to reinforce repairs under pressure.

These kits work on a variety of pipe materials used in industrial settings, such as:

- Pipe Material – Common Industrial Uses.

- Steel – Widely used in chemical processing and oil & gas pipelines due to its durability and strength.

- Stainless Steel – Ideal for food processing and pharmaceutical industries, offering corrosion resistance and hygiene.

- PVC – Common in water treatment plants and cooling systems, thanks to its lightweight and non-corrosive nature.

- Copper – Used in heating systems and industrial plumbing due to its excellent thermal conductivity and reliability.

The design of Shree Ram Pipe Repair Kit makes them easy to use, even in high-stakes environments like power plants or chemical factories. Here’s the process:

- Prepare the Pipe – Clean the leak area thoroughly to remove dirt, grease, or chemicals for a strong seal.

- Activate the Bandage – Soak the fiberglass bandage in water to activate the resin and squeeze out any excess water.

- Wrap the Leak – Tightly wrap the bandage around the pipe, overlapping each layer by about half its width.

- Smooth and Secure – Press the wrap firmly to eliminate air bubbles and ensure a smooth, even seal.

Hardening Time – Within 30 minutes, the bandage forms a pressure-resistant and chemical-resistant seal that can handle water, oil, steam, or gases, making it ideal for fast industrial leak repairs.

Benefits for Industries and Distributors

Shree Ram Pipe Repair Kit offer significant advantages for industrial facilities and their distributors:

- Zero Downtime Solutions: Repair leaks without shutting down critical systems, maintaining production schedules.

- Cost-Effective Repair: Avoid expensive emergency plumbing services or full pipe replacements.

- Prevents Damage: Stops leaks quickly to prevent water damage, equipment corrosion, or chemical spills.

- Versatile Applications: Suitable for pipes of all sizes and materials, from steel in chemical plants to concrete in wastewater systems.

- Professional Grade: WRAS-approved for safe use in potable water systems and robust enough for harsh industrial environments.

For distributors, these kit are a high-demand product, offering a reliable solution to sell to industries needing emergency preparedness.

Applications in Industrial Settings

The designers tailored Shree Ram Pipe Repair Bandages for high-stakes environments.

- Power Plants: Fix leaks in cooling or steam lines to maintain energy production without interruptions.

- Chemical Factories: Seal pipelines carrying hazardous materials, preventing leaks that could pose safety risks.

- Oil and Gas Facilities: Repair pipelines under pressure, ensuring system integrity and avoiding costly shutdowns.

- Industrial Infrastructure: Strengthen aging pipes in wastewater or processing systems, extending their lifespan.

These bandages provide leak sealing solutions that minimize disruption and ensure safety.

Here are real-world examples of how Shree Ram Pipe Repair kit make a difference:

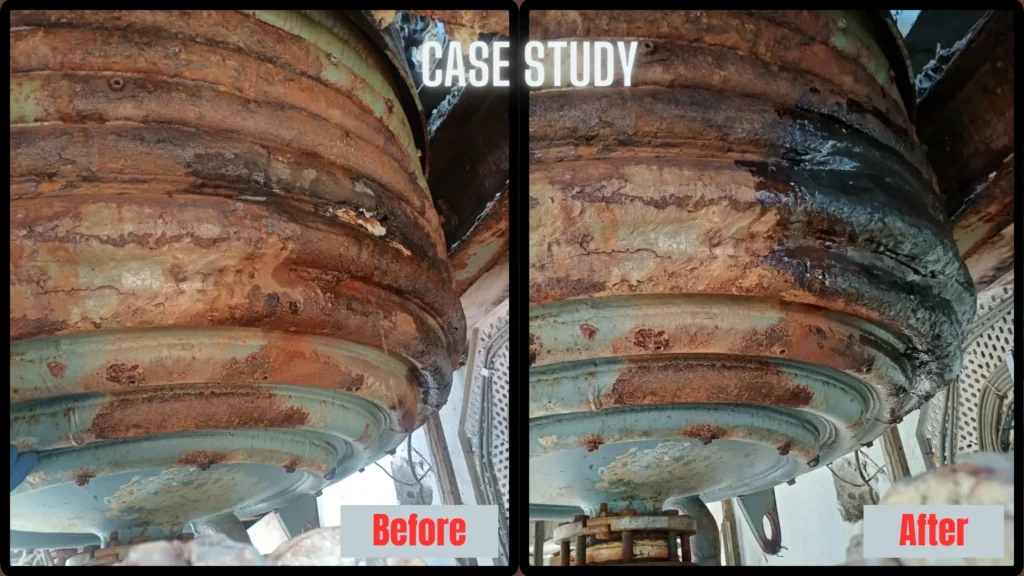

1. Power Plant Emergency:

A power plant faced a pinhole leak in a steel cooling pipe. Shutting down the system would have delayed electricity production. The maintenance team used Shree Ram Pipe Repair Bandages to seal the leak in under an hour, keeping the plant operational and avoiding downtime costs.

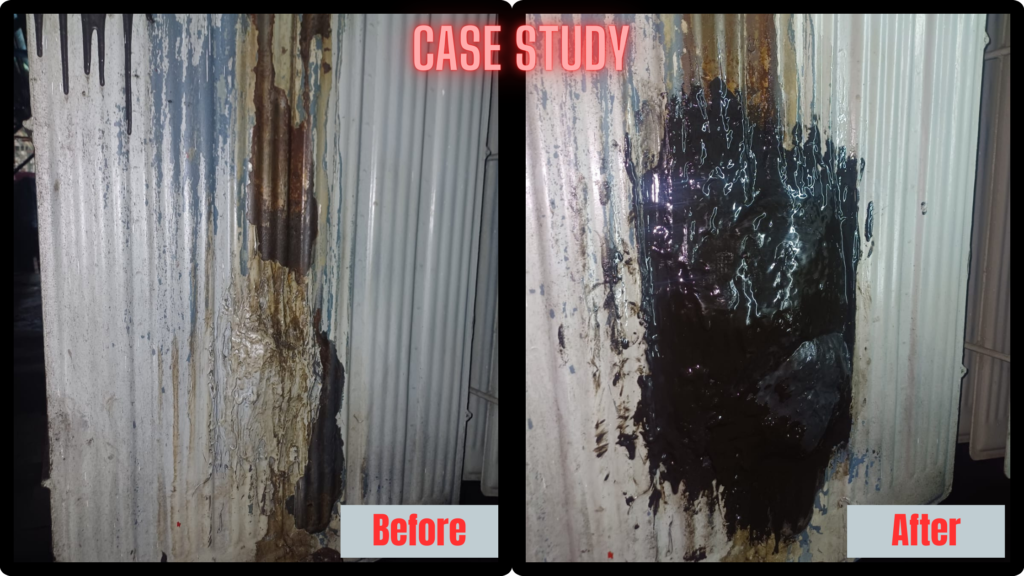

2. Chemical Factory Fix:

A chemical factory detected a crack in a stainless steel pipeline carrying corrosive materials. Using a live leak repair kit with Shree Ram bandages, the team sealed the leak without stopping production, preventing a hazardous spill and maintaining safety compliance.

- Stock for Emergencies: Keep kits readily available for quick deployment in plumbing emergencies.

- Train Teams: Ensure maintenance staff are familiar with the simple application process.

- Promote Versatility: Highlight the bandages’ ability to handle various pipe materials and substances to attract diverse clients.

- Ensure Compatibility: Verify the kit suits the specific pressures and chemicals in your facility.

For industries like power plants, chemical factories, and oil and gas facilities, pipe leaks can be a costly nightmare. Shree Ram Sealing engineers Pipe Repair kit provide a fast, reliable, and cost-effective solution to keep operations running smoothly. Available through distributors at onlineleaksealingservice.com, these bandages are a must-have for emergency pipe repair, offering durability and ease of use for maintenance teams. Don’t let leaks slow you down—equip your facility with Shree Ram Pipe Repair Bandages and stay prepared.