Stop Leak in 30 Minutes: Our Pipe Repair Kit Fixed the Problem Fast

A very important pipe breaks in a factory. Liquid shoots out with very strong pressure. If they turn off the pipe, the whole factory stops. This costs lots of money every hour. Everyone got very worried. This really happened to one of our customers. But they stopped a big accident. The factory kept working normally. The leak was fixed for good. All this took just 30 minutes. How? Because of Our SR High Strength Pipe Repair Kit. This is why every factory needs this emergency helper.

Key Benefits:

- Zero Tolerance for Shutdown: Stopping the flow meant stopping production – an unacceptable cost of thousands per hour in lost output.

- Pressure Intact: Releasing system pressure wasn't an option; it would disrupt the entire process.

- Speed is Survival: Every minute of leakage means wasted product, potential safety hazards, and environmental risks.

- Strength & Longevity Required: The repair couldn’t be a temporary band-aid; it needed to withstand the harsh chemicals and constant high pressure permanently.

Products Kit:

- Superfast Epoxy Putty: For plugging larger gaps or irregularities once contained.

- Wrap & Seal Pipe Burst Tape: The critical first responder – self-amalgamating tape that bonds instantly to itself and the pipe under pressure.

- SR High Strength Pipe Repair Bandage: A resin-infused fiberglass bandage that creates an incredibly durable, impact-resistant outer shell.

The 30-Minute Miracle: Step-by-Step Leak Sealing

Here’s the breakdown of how our team transformed a potential disaster into a controlled success in less time than a lunch break:

Key Benefits:

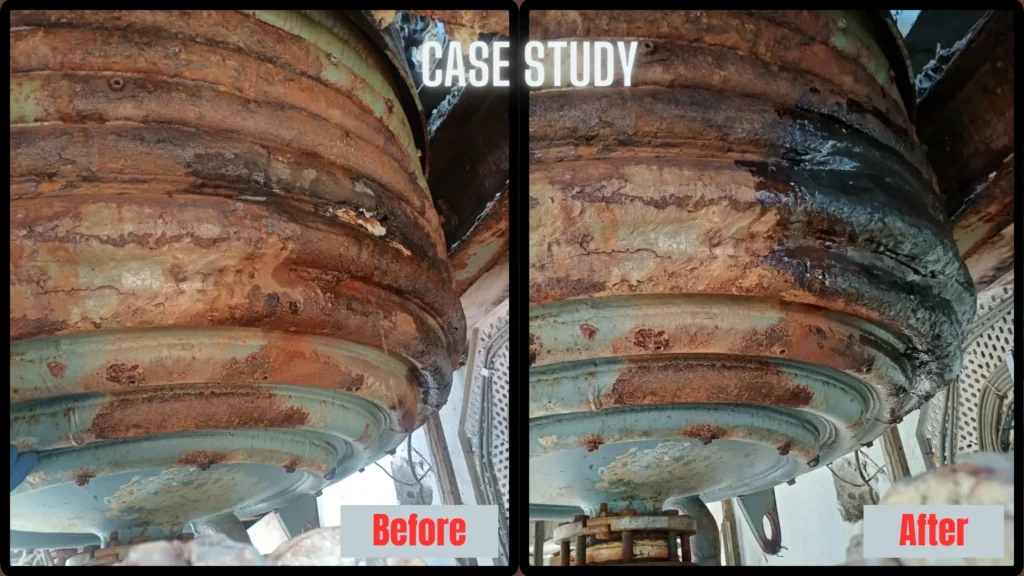

- Action: The area around the leak was vigorously cleaned using a wire brush to remove rust, scale, paint, and debris, followed by wiping with a clean, dry cloth.

- Why it Matters: Adhesion is everything. A clean, slightly roughened surface ensures the repair materials bond directly to the pipe substrate, not to contaminants. Skipping this step drastically increases the risk of failure, especially under pressure.

Key Benefits:

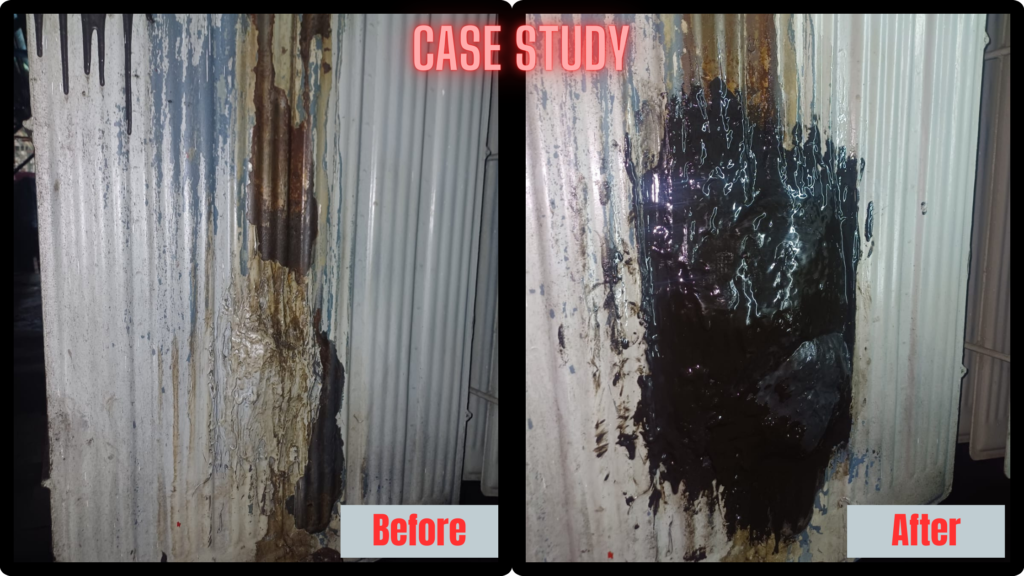

- Action: With the system still live and pressurized, the Wrap & Seal Pipe Burst Tape was stretched tightly (activating its self-amalgamating properties) and wrapped directly over the leak source. Multiple layers were applied, building thickness and pressure resistance.

- Why it Matters: This tape is the key to live leak sealing. It fuses into a solid, rubber-like barrier instantly, even on wet surfaces under pressure. The stretching creates molecular bonding, forming a seamless, watertight seal that immediately reduces flow. Multiple layers easily push its pressure rating beyond 30 bar.

Key Benefits:

- Action: The SR High Strength Pipe Repair Bandage was submerged in water to activate its resin. It was then tightly wrapped over the taped area, ensuring full coverage and overlap.

- Why it Matters: While the tape stops the leak, the bandage provides permanent, structural reinforcement. The water-activated resin cures rock-hard in just 5 minutes, creating a rigid, impact-resistant, and vibration-proof exoskeleton. This layer absorbs stress, protects the tape, and guarantees long-term integrity against chemical exposure and pressure surges.

Key Benefits:

- Action: Ensuring the bandage was smoothly applied and fully saturated, the team monitored the initial set. The epoxy putty was ready if needed for filling, but the tape and bandage proved sufficient.

- Why it Matters: Full curing continues over the next few hours, but the repair gains significant strength within minutes, allowing immediate pressure restoration.

The Result: Zero Leakage, Zero Downtime, Zero Hassle

Mission accomplished in under 30 minutes.

- No Shutdown: Production never stopped. The process flow continued uninterrupted.

- No Leakage: A rigorous pressure test confirmed the repair easily withstood over 30 bar – exceeding the original operating pressure – with zero leaks.

- Immediate Operations: The plant resumed full, normal operations instantly after the repair.

- Permanent Solution: This wasn't a temporary fix. The repair provided a robust, long-lasting seal designed to endure the plant's harsh conditions.

- Empowered Team: Before leaving, we trained the plant's maintenance staff on using the pipe repair kit, ensuring they were ready for any future emergencies.

Real-World Applications: Where This Pipe Repair Kit Shines

The versatility of this kit makes it indispensable across numerous sectors facing pipe emergencies:

- Power Generation Plants: Fixing boiler feed lines, condenser tubes, cooling water pipes under pressure.

- Oil & Gas Refineries/Rigs: Sealing leaks on critical hydrocarbon, water injection, or utility lines, onshore and offshore.

- Chemical & Pharmaceutical Manufacturing: Containing hazardous chemical leaks safely and quickly.

- Water & Wastewater Treatment: Repairing mains, pump discharge lines, clarifier pipes without service interruption.

- Commercial Buildings & Municipal Infrastructure: Emergency repairs on mains, heating systems, fire sprinkler lines.

- Household Plumbing: Tackling sudden bursts or major leaks before a plumber arrives.

A major pipe leak doesn't have to cause disaster, costly downtime, or huge repair bills. With the right Pipe Repair Kit, you can fix leaks fast—in just 30 minutes. Shree Ram Sealing Engineers kit acts like strong protection for your pipes. It lets your team seal leaks immediately, even under pressure, keeping your plant running. Don’t risk downtime. Trust the solution industry leaders use. Be leak-ready in 30 minutes.