Transformer Oil leaks repair Services

We Help your assets for a better life cycle

Expert Transformer Oil Leak Repair Services

TRANSFORMER OIL LEAKS

How We Do It

Benefits of Our Services

Our Solution

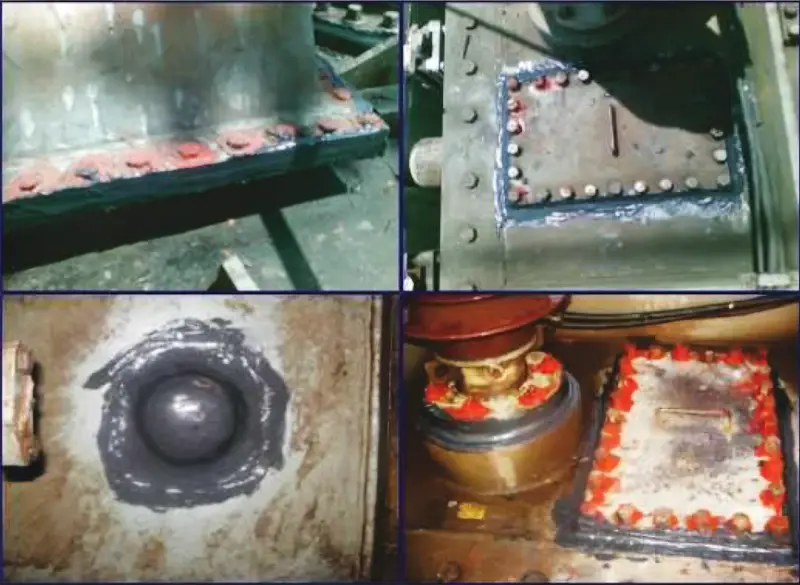

At Shree Ram Sealing Engineers, we offer specialized transformer oil leak services that minimize downtime and reduce costs. Our advanced cold welding technology provides a fast, effective, and permanent solution for sealing transformer oil leaks without the need for extensive disassembly or oil drainage.

Why Choose Us?

-

Quick and Efficient Repairs:

Our methods eliminate the need to take transformers out of service for weeks. Instead, we offer a rapid solution that keeps your operations running smoothly.

-

Cost-Effective:

Avoid the high costs associated with traditional repair methods, including the expense of large crews and specialized equipment.

-

Environmental Safety:

By preventing oil leaks, we help protect the environment from potential oil contamination.

-

Minimal Downtime:

Our solutions are designed to get your transformers back in service quickly, reducing the impact on your operations.

-

Non-Invasive Methods:

Using our cold welding technology, we can repair leaks without the need for hot work, ensuring a safer maintenance process.

Transformer Oil Leak Services

We offer specialized transformer oil leak services that minimize downtime and reduce costs.

Transformer Oil Leak Services

Online Leak Sealing Services

Transformer Oil Leak Services

Online Leak Sealing Services

Contact our technical expert for a customized solution to your operational challenges